LOTO Procedure: A Complete Guide to Lockout Tagout for Workplace Safety

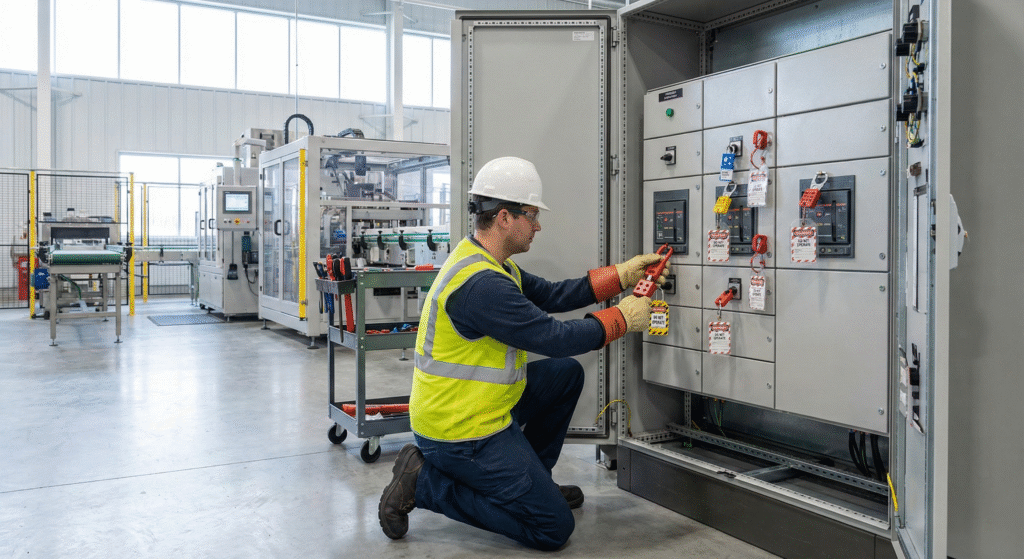

Accidental machine start-up is one of the most common causes of serious workplace injuries in industries such as manufacturing, construction, utilities, and maintenance. Many incidents occur not because machines are faulty—but because energy sources were not properly controlled during servicing or repair.

This is exactly why the LOTO procedure (Lockout Tagout) exists.

If you are a safety officer, maintenance engineer, supervisor, or employer, understanding the LOTO procedure step by step is essential—not just for compliance, but for saving lives.

This article explains the LOTO procedure in simple terms, with real-world context, actionable steps, and best practices.

What Is a LOTO Procedure?

The LOTO procedure is a systematic safety process used to isolate and control hazardous energy during maintenance, cleaning, servicing, or repair of machines and equipment.

LOTO stands for:

Lockout – Physically locking energy-isolating devices

Tagout – Clearly tagging the lock to warn others not to operate the equipment

The goal is simple:

✅ Ensure machines cannot start unexpectedly

✅ Prevent release of stored or residual energy

✅ Protect workers from electrocution, crushing, burns, or amputations

Why Is the LOTO Procedure Important?

Without a proper lockout tagout procedure, workers are exposed to:

Unexpected machine start-up

Electrical shock

Hydraulic or pneumatic pressure release

Mechanical movement of parts

Serious injuries or fatalities

Real-World Impact

Many workplace accident investigations reveal one common cause:

“Equipment was believed to be isolated but was not properly locked or verified.”

A well-implemented LOTO procedure eliminates this assumption risk.

Types of Hazardous Energy Controlled in LOTO

| Energy Type | Examples |

|---|---|

| Electrical | Power supply, capacitors |

| Mechanical | Rotating shafts, flywheels |

| Hydraulic | Pressurized fluids |

| Pneumatic | Compressed air |

| Thermal | Steam, hot surfaces |

| Chemical | Chemical reactions, pipelines |

| Gravitational | Raised machine parts |

Step-by-Step LOTO Procedure (Standard Method)

Step 1: Preparation for Shutdown

Identify all energy sources connected to the equipment

Understand machine drawings and operating manuals

Inform affected employees about the shutdown

✅ Planning prevents missed energy sources

Step 2: Equipment Shutdown

Switch off the machine using normal operating controls

Follow standard shutdown procedures

✅ Machine must be fully stopped before isolation

Step 3: Isolation of Energy Sources

Disconnect power supplies

Close valves

Block mechanical movement

✅ Equipment must be separated from all energy sources

Step 4: Apply Lockout and Tagout Devices

Attach lockout devices to isolators

Each authorized worker applies their own personal lock

Attach a tag with:

Name

Department

Date

Reason for lockout

✅ One lock = one worker = full accountability

Step 5: Release Stored or Residual Energy

Discharge capacitors

Relieve hydraulic or pneumatic pressure

Block moving parts

✅ Stored energy is often the most dangerous

Step 6: Verification (Try-Out Step)

Attempt to start the equipment using normal controls

Confirm that the machine does NOT operate

✅ Never skip verification – it saves lives

Step 7: Perform Maintenance or Servicing

Complete work safely while equipment remains locked

Locks must stay in place throughout the task

Step 8: Removal of Lockout Tagout

Ensure work is completed

Inspect area for tools and personnel

Remove locks only by the person who applied them

Inform affected employees before restart

✅ Controlled restart prevents secondary incidents

LOTO Procedure Flow Table

| Stage | Key Action | Responsibility |

|---|---|---|

| Preparation | Identify energy sources | Authorized person |

| Shutdown | Stop machine | Operator |

| Isolation | Disconnect energy | Authorized person |

| Lock & Tag | Apply lock + tag | Each worker |

| Energy Release | Neutralize stored energy | Authorized person |

| Verification | Test isolation | Authorized person |

| Work Execution | Maintenance task | Assigned team |

| Restart | Safe re-energization | Supervisor |

Common LOTO Procedure Mistakes (And How to Avoid Them)

❌ Using tags without locks

❌ One lock used for multiple workers

❌ Skipping stored energy release

❌ Not verifying isolation

❌ No written LOTO procedure

✅ Solution:

Written LOTO procedures

Worker training

Periodic audits

Proper lockout devices

When Is LOTO Required?

LOTO procedures must be used when:

Servicing machines

Performing preventive maintenance

Cleaning or replacing parts

Clearing jams

Repairing energized equipment

If any employee could be injured by unexpected energy release, LOTO is required.

LOTO Procedure vs Permit to Work (PTW)

| Aspect | LOTO Procedure | Permit to Work |

|---|---|---|

| Purpose | Energy isolation | Activity authorization |

| Focus | Machine safety | Overall task control |

| Requirement | Mandatory for hazardous energy | Used for high-risk tasks |

| Ownership | Maintenance & safety | Management & supervision |

✅ Best practice: LOTO + PTW together

Who Needs Training on LOTO Procedures?

LOTO training is essential for:

Maintenance technicians

Electricians

Machine operators

Safety officers

Supervisors

Training ensures:

✔ Correct application

✔ Legal compliance

✔ Reduced accidents

Frequently Asked Questions (FAQs)

LOTO stands for Lockout Tagout, a safety procedure to control hazardous energy during maintenance.

Yes. LOTO is required under most occupational health and safety regulations worldwide whenever hazardous energy is present.

Only in rare cases where locking is not possible—and only with additional safety controls. Lockout is always preferred.

Only the person who applied the lock, except under a clearly documented emergency procedure.

At least annually or whenever equipment or processes change.

Final Thoughts: LOTO Is Not Paperwork—It’s Protection

A LOTO procedure is not just a document for audits. It is a life-saving system that protects workers from invisible but deadly hazards.

Organizations that implement effective lockout tagout procedures experience:

Fewer accidents

Better compliance

Higher workforce trust

Strong safety culture

If your workplace uses machines, energy sources, or maintenance teams, LOTO is non-negotiable.

Control energy. Protect lives. That is the purpose of the LOTO procedure.